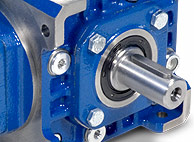

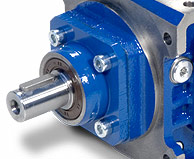

R SeriesBevel Right Angle Reducer - Gearboxes & Gearmotors | ||

|

|

|

|

Product of Bologna, Italy |

R Series is considered by some the ultimate "Miter Box" for its modular design. Designers have Tramec's six machined sides, flange, torque-arm, foot, and shaft outputs, as well as shaft, coupled flange, and close flange inputs to access the R series 1, 2.5, 5, and 10/1 ratios for a wide range right angle drive applications. A high-efficiency, quiet, maintenance free Gleason spiral-bevel set fit inside of a gasket free modular gear case made of near net engineered cast-iron gives any machine designer peace of mind. Using our on-line CAD drawing tool, and knwing TVT's commitment to fast assembly & ship, gives our clients the"at hands reach" solution for their competitive advantage. When our clients win... we do ok too. By design, our R series is Servo friendly, with a reduced backlash of <8 Arc Minutes suitable to many right-angle servo applications... at a great price. | |

|

| |

| R Spiral Bevel Reducers is available in five standard sizes from 19 to 48mm output shafts (3/4 to 1-7/8"), ratios 1, 2.5, 5, and 10/1, left, right, double, and hollow output shafts, as well as shaft, flanged, and close coupled input types for IEC Induction and Servo motors. The Spiral Bevel Gleason machined gears are highly efficient and have an excellent thermal rating running in synthetic lubricants. Angular backlash of 12 ~ 20 arc minutes is standard, with a reduced backlash of <8 arc minutes available for your precision motion control applications. Low inertia is inherent to the R, as is fast delivery from modular assembly of common parts. | ||

|

| |

| ||

| a | Documentation R Series | |

Click Catalog Selection for PDF |

Designation | 141 KB |

| Performance & Technical Specifications | 121 KB | |

SERVICE LINKS |

Dimensions | 162 KB |

| Accessories | 159 KB | |

| x | Service Parts Diagram | 400 KB |

| z | Lubrication Instruction | 159 KB |

| Radial & Axial Loads | 90 KB | |

| a | Moments of Inertia | 181 KB |

| a | Engineering Information & Factors | 213 KB |

| a | R Series Catalog (All of Above) | 1.5 MB |