| Z Series Parallel Helical Reducer - Gearmotor - Riduttori | |||

|

| ||

| |||

|

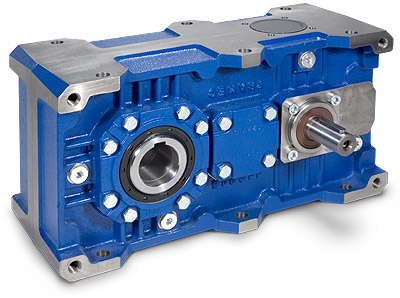

The Z Series is introducing America to six side universal mount modular assembly gearboxes for medium duty industrial prime movers. High precision & quality automated manufacturing cells allow Tramec to manufacture the components in high volume, maximizing production efficiencies & systems for quality, while pushing costs down. From the machine designers perspective, this means a high performance gearbox can compete with lower end worm or helical gearboxes for price, yet offer the fast delivery made possible from Order-Assemble-Ship production. Backstops, Output Flanges, Motorized Inputs, single or double output shafts, and multiple mounting positions are assembled to suit... no waiting for metal to be cut. | ||

| |||

| Z Series is available in eleven (11) sizes, single, double, triple stages ranging from 5 to 250/1 ratios to provide ideal mix of ratio, service factor, and compact size for many applications. Standard Synthetic Lubricant for 20,000 hours maintenance free service, as well as a wide array of accessories for backstop, bearing covers, torque-arm, flange mounts, servo input, shrink disc output, and hydraulic, PMDC, and AC Gearmotors. | |||

| |||

| |||

| a | Documentation Z Series | ||

Click Catalog Selection for PDF |

Designation | 118 KB | |

| Performance & Technical Specifications | 94 KB | ||

SERVICE LINKS |

Dimensions | 154 KB | |

| Accessories | 243 KB | ||

| Service Parts Diagram | 488 KB | ||

Call TVT Engineer |

Lubrication Instruction | 105 KB | |

| Radial & Axial Loads | 133 KB | ||

| a | Moments of Inertia | 102 KB | |

| a | Engineering Information & Factors | 213 KB | |

| a | Z Series Catalog (All of Above) | 2.0 MB | |

|