| Becker |

Kw Range |

Hp Range | Speed Range |

Becker drive units RK,

RKN for 5.5 to 150Kw motor ratings, comprising mechanically

adjustable regulating pulley R with integral central

adjustment and either Spring loaded automatic torque

dependent regulating pulley K or

KN with increased diameter for lower output speeds.

The axial pressure on the V-Belt is exerted by compression

springs with optimally dimensioned characteristics.

The driving system is suitable for reversing operation. The K - KN tensioning pulleys are uniquely suited to high starting torques and overload protection safety.

|

| RK3 | 4 ~ 5.5 | 5.5 ~ 7.5 | 8/1 | |

|

RKN34 |

5.5 | 7.5 | 5/1 | |

| RK4 | 7.5 ~ 11 | 10 ~ 15 | 8/1 | |

| RKN45 | 11 | 15 | 6/1 | |

| RK5 | 11 ~ 15 | 15 ~ 20 | 8/1 | |

| RKN56 | 18.5 | 25 | 5.4/1 | |

| RK6 | 22 ~ 30 | 30 ~ 42 | 8/1 | |

| RKN67 | 30 ~ 37 | 40 ~ 50 | 5.5/1 | |

| RKN68 |

37 |

50 |

5.2/1 | |

| RK7 | 37 ~ 55 | 50 ~ 75 | 6/1 | |

| RNK78 | 45 ~ 55 | 62 ~ 75 | 5.2/1 | |

| RK8 | 55 ~ 75 | 50 ~ 100 | 5/1 | |

| RNK89 | 75 | 100 | 4/1 | |

| RK9 | 90 ~ 150 | 125 ~ 200 | 3/1 |

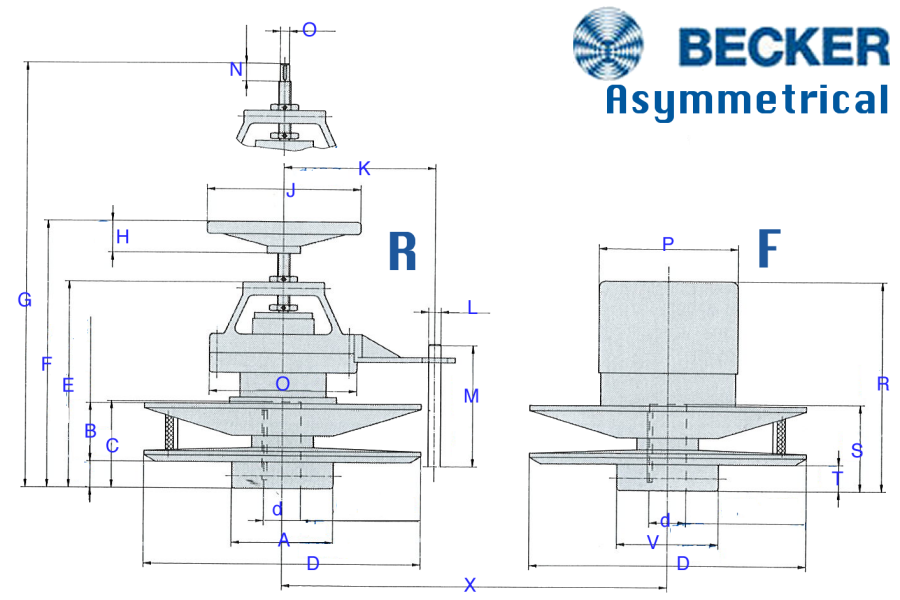

| Mechanically

Infinitely Variable Speed Units with Broad V-Belts,

BECKER System. Optimum product quality and

operational safety for all fields of application in

machine and plant construction is achieved by infinitely

variable speed control of motors to 150kW. There

are good reasons why the Berges BECKER System is

obviously superior. As against conventional

systems, BECKER variable speed units with asymmetric

profile have definite advantages. The asymmetric

system with the 2 degree sheave attached to the shaft

and the axially moving 18 degree sheave ensures

that the tensile forces of the belt are acting very

close to the shaft bearings. The bending

moment acting on the free shaft ends is small and does

not change when the pulleys are varied. In

accordance with the pulleys asymmetric broad V-belts are

used. As against conventional systems asymmetric BECKER V-belts have a smaller volume, which means:

The driven pulley with torque curve is another eminent feature of the product diversity of BECKER variable speed drives. The axial contact pressure rises so that sliding of the V-Belt during impact (SHOCK LOAD) or overload or start of machines with the great moments of inertia avoided. Very high efficiency also during partial load operation as well as a considerably longer service life of the belt is ensured by the BECKER driven pulley with torque curve. For more than 25 years, BECKER variable speed drives have been used successfully all over the world. The investments made in the recent past and planned for the future to guarantee a constant good quality in the long run give a clear signal. BERGES concentrates on the production of mechanical infinitely variable speed drives and has expanded its production program in order to meet the requirements of the market. TVT-America is well established as a Engineering, Marketing, and Distribution center for the Berges Becker Systems in North America. For assistance in your application, please contact TVT today. Engineering@tvtamerica.com, or simply call our toll free number at your earliest convenience to begin discussions regarding your unique application. |

|

Berges Becker Asymmetrical V-Belt Pulley DrivesBecker Antiriebe GMBHThere are good reasons why the Becker system is obviously superior. As against conventional systems Becker Variable SPeed units with asymmetric profile have definite advantages. The asymmetric systems with the 2 degree sheave attache to the shaft and the axially moving 18 degree sheave ensures that the tensile forces of the belt are acting very close to the haft bearings.The bending moment acting on the free shaft ends is small and does not change when the pulleys are varied. In accordance with the pulleys asymmetric broad V-Belts are used. As against conventional systems asymmetrical BECKER V-Belts ahve a smaller volume, which means more lateral rigidity, lower centrifugal forces, less internal heating, and thus more loading capacity and longer service life of the asymmetric Becker V-belt.As against gear drives with sheaves of the same angle, installation and pulley alignment are very easy. With the asymmetric BECKER variable speed units pulley alignment is achieved automatically and can be easily checked by lining the back of the 2 degree sheaves of both pulleys with a ruler. The driven pulley with torque curve is another eminent feature of the product diversity of Becker variable speed drives. Theaxial contact pressure of the V-belt required for the respective power tranmission is automatically adjusted by this toruq dependent device. With increasing torque the axial contact pressure rises so that sliding of the v-belt during impact or overlad or start of machines with great moments of inertia is avoided. Very high efficiency also during partial load operation as well as a considerably longer service life of the belt is ensured by the Becker driven pulley with torque curve. For more than 25 years, Becker variable speed drives have been used successfully all over the world. The investments made in the recent past and planned for the future to guarantee a constat good quality in the long run give a clear signal: Berges-Becker will concentrate on the production of mechanically infinitely variable speed drives also in the future and expand the production program in order to meet the requirements of the market. This is another eature that distinguishes us from our competitors.

|