H SeriesHelical Worm Universal Mount Gear Reducers |

||

|

|

|

|

|

|

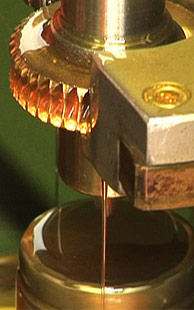

Tramec Series "H" helical worm gear speed reducers are an exciting new range of aluminum worm gear reducer and cast iron worm gear reducer for the TVT Group around the globe. While directly interchangeable to the old fashioned NMRV, the - H range is heat sink free (easier to clean, less opportunity to collect dirt), and paint free (corrosion resistance cast into alloy) and machined on six sides for precision universal mounting. H types available in easy to service "coupling" style input, as well as single and double input shafts, and the H helical primary design is unique to Tramec and is known as a reliable, low cost, efficient, easy to use high ratio helical/worm gearbox....available quickly!!! 1 or many pieces. | |

|

|

|

|

| H series is designed in a modular vacuum diecast gearcase, leak free, and machined on fully automated CNC machining centers to provide a product that is readily adaptable, quick to assemble, and very cost competitive via a design & manufacture advantage approach. We can quickly assemble standard parts into a near infinite combination of input, output, ratio, and mounting configuration to suit your need exactly... and ship quickly one piece or many. Creative solutions, such as double output flanges, double input flanges, one motor with two reducers in AC or DC gearmotors, with our without brakes, can be created quickly without high expense. | ||

|

|

|

|

| a | Documentation H Series |

|

| a | Characteristics of H Series | 53 KB |

|

Click Catalog Selection for PDF |

Designation | 197 KB |

| Lubrication | 251 KB | |

| a | Technical data & performance rating | 113 KB |

|

Moments of inertia | 81 KB |

| Dimensions | 198 KB | |

| Additional input (Double extended high speed shaft) | 105 KB | |

|

Accessories | 60 KB |

| Spare parts list | 111 KB | |

| a | a | |

| H Series Catalog (All of Above | 665 KB | |

.jpg)